Understanding Buck Converters: The Key to Efficient Power Supply in Modern Electronics

As the demand for energy-efficient power electronics continues to rise, the buck converter has emerged as a pivotal technology in modern devices. According to a report by Grand View Research, the global power electronics market is projected to reach $1 trillion by 2025, driven largely by the increasing adoption of high-efficiency power supply solutions like buck converters. These devices, known for their ability to step down voltage while maintaining high efficiency often exceeding 90%, are integral in applications ranging from consumer electronics to electric vehicles. Furthermore, the International Energy Agency (IEA) highlights that efficient power conversion can significantly reduce energy losses, making buck converters not only a technical necessity but also a critical component in the pursuit of sustainability in electronic design. Understanding the mechanics and benefits of buck converters is therefore essential for engineers and designers looking to optimize their power supply systems in an increasingly energy-conscious market.

How Buck Converters Work: Principles of Voltage Regulation

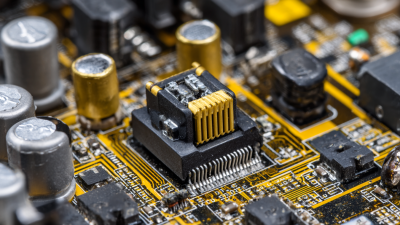

Buck converters, also known as step-down converters, play a crucial role in voltage regulation, enabling devices to operate efficiently while consuming less power. At their core, buck converters use a switching element, a diode, an inductor, and output capacitors to convert a higher input voltage to a lower output voltage. According to a report by MarketsandMarkets, the global power converter market is projected to reach USD 30 billion by 2025, underscoring the increasing reliance on efficient power supply solutions in modern electronics.

The operational efficiency of buck converters typically exceeds 90%, making them ideal for battery-powered and low-power applications. They leverage pulse-width modulation (PWM) techniques to regulate the output voltage by adjusting the duty cycle of the switching element. When the duty cycle increases, the average output voltage rises, while a decrease results in a lower output voltage. With advancements in semiconductor technology, such as gallium nitride (GaN) and silicon carbide (SiC), the performance of buck converters continues to improve, with notable increases in switching speeds and reductions in size. The International Energy Agency (IEA) has reported that by optimizing power management through devices like buck converters, energy consumption in electronics could be reduced by 30% in the coming decade.

Key Components of Buck Converters: Understanding Inductors and Capacitors

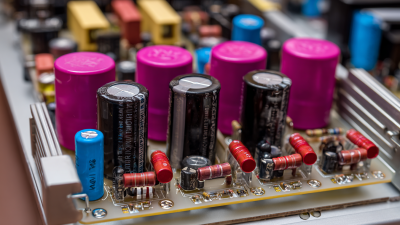

Buck converters are pivotal in the design of modern power supply systems, particularly due to their efficiency in voltage regulation. At the heart of a buck converter are two key components: inductors and capacitors.

Inductors play an essential role in energy storage during the switching cycle, allowing for smooth conversion of higher input voltages to lower output levels. According to a recent report by Mordor Intelligence, the global inductor market's value is expected to reach USD 2.8 billion by 2026, underscoring the increasing demand for efficient power management solutions in electronic devices.

Capacitors are equally important, as they filter out voltage ripples and stabilize the output voltage. They provide a reservoir of charge, ensuring that the buck converter delivers a consistent output even with fluctuating input conditions. The research firm MarketsandMarkets highlights that the capacitor market is projected to grow significantly, estimated to reach USD 60 billion by 2025, driven by the rising demand for consumer electronics and electric vehicles. Understanding the roles of inductors and capacitors in buck converters is essential for engineers to enhance power efficiency and improve the overall performance of electronic devices in various applications.

Efficiency Analysis: Comparing Buck Converters to Linear Regulators

When comparing power supply options for modern electronics, buck converters emerge as a highly efficient alternative to linear regulators. Buck converters utilize a switching mechanism to efficiently step down voltage while minimizing energy loss as heat. This capability allows them to maintain high efficiency, often above 90%, making them particularly advantageous for battery-operated devices and applications requiring a stable output voltage with minimal power consumption.

In contrast, linear regulators provide a simpler design with fewer components, resulting in lower initial costs and ease of implementation. However, their efficiency tends to diminish significantly as the difference between input and output voltages increases, often leading to wasted power in the form of heat. This inefficiency can pose challenges in terms of thermal management and can reduce overall system performance. As power density and device miniaturization continue to be critical in modern electronics, the preference for buck converters over linear regulators is increasingly evident in applications where efficiency is paramount.

Understanding Buck Converters: The Key to Efficient Power Supply in Modern Electronics - Efficiency Analysis: Comparing Buck Converters to Linear Regulators

| Parameter | Buck Converter | Linear Regulator |

|---|---|---|

| Efficiency (%) | 85-95 | 30-60 |

| Heat Dissipation | Low | High |

| Size | Compact | Relatively Larger |

| Cost | Medium | Low |

| Load Regulation | Excellent | Good |

| Current Rating (A) | Up to 50+ | Up to 5 |

Selecting the Right Buck Converter: Factors to Consider

When selecting the right buck converter for a specific application, several critical factors come into play. First, understanding the output voltage and current requirements is essential. Buck converters are designed to efficiently step down voltage while providing sufficient current for the load; hence, the specifications must align closely with the demands of the circuit. Ensuring that the buck converter can handle the intended load without throttling performance is crucial for maintaining efficiency and reliability.

Additionally, considerations around thermal management and efficiency ratings should not be overlooked. The converter's efficiency significantly affects power dissipation, impacting the thermal performance and overall reliability of the electronic device. High-efficiency buck converters reduce heat generation, allowing for a more compact design and potentially lower cooling requirements.

Furthermore, assessing features such as control type (voltage mode vs. current mode), transient response, and protection mechanisms (like over-voltage and short-circuit protection) can influence the choice. Balancing these factors will guide engineers in selecting an optimal buck converter tailored to their specific needs.

Common Applications of Buck Converters in Modern Electronics

Buck converters, also known as step-down converters, play a crucial role in the efficiency of power supply in modern electronics. These devices are widely used across various applications, from consumer electronics to industrial systems. One of the most common applications is in portable devices, such as smartphones and laptops, where they manage the battery power effectively, converting high voltages down to levels suitable for the devices’ components. This efficiency extends battery life, which is a primary concern for manufacturers and users alike.

In industrial settings, buck converters are employed in power management systems to supply consistent voltage to sensors and controllers. Their ability to produce a stable output despite varying input conditions makes them ideal for automation systems, where reliability is essential. Additionally, they find usage in electric vehicles, ensuring that the battery packs deliver power efficiently to the motors while maintaining thermal management.

Tip: When selecting a buck converter for your project, consider the efficiency ratings and thermal performance to ensure optimal operation. Also, evaluate the input and output voltage ranges to match your application’s specific needs. Using a buck converter not only enhances performance but also extends the lifespan of your electronic components.

Related Posts

-

10 Digital Best Practices for Enhancing Your Buck Converter Efficiency

-

How to Select the Best Buck Converter for Efficient Power Management in Your Application

-

Exploring the Future of Buck Converters at China's 138th Canton Fair 2025: Industry Insights and Innovations

-

Addressing Common Issues with DC Supply Systems: A Comprehensive Guide

-

Discover the Advantages of Implementing UPS Power Solutions for Your Business

-

Understanding DC Power Supply: Key Components and Their Impact on Modern Electronics

At Premium PSU, we are specialists in designing and manufacturing power conversion systems for the industrial market. Our product range includes high reliability power supplies from 50W to 72kW.

PREMIUM PSU

C/ Dolors Aleu, 19-21, 2nd Floor

08908 – Hospitalet de Llobregat

Barcelona-SPAIN

t.+34 93 223 26 85