Maximize Efficiency with These Digital Strategies for Your Programmable Power Supply Usage

In today’s fast-paced technological landscape, maximizing efficiency in electronic testing and development has become paramount, particularly for industries relying on programmable power supplies. As reported by the Global Power Supply Industry Report, the market for programmable power supplies is projected to grow at a CAGR of 8.2% from 2021 to 2028, driven by the increasing demand for precision in power management across various sectors. With innovations spurred by digital transformation, implementing effective digital strategies for programmable power supply usage can significantly enhance operational efficiency and reduce time-to-market. This blog delves into key digital techniques and best practices to optimize the performance of programmable power supplies, empowering engineers and businesses to stay competitive in an increasingly automated world.

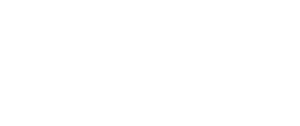

Understanding the Basics of Programmable Power Supplies: Key Features and Benefits

Programmable power supplies (PPS) are essential components in modern electronics, offering flexibility and precision in voltage and current delivery. Understanding their key features and benefits can significantly enhance efficiency in various applications, especially in high-performance environments like AI servers and data centers. PPS allows for precise control, which is particularly important as the demand for stable and efficient power continues to rise in the AI server market, ensuring optimal performance for large clusters.

To maximize the utility of programmable power supplies, consider implementing digital control techniques. This modern approach allows for better response times and increased accuracy compared to traditional analog methods. By utilizing digital signal controllers, engineers can fine-tune power delivery parameters, allowing for enhanced adaptability to different operational conditions.

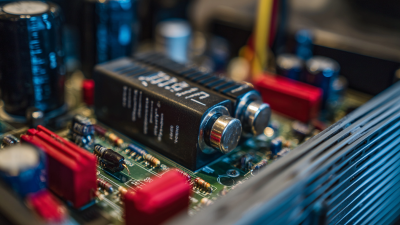

Additionally, keep abreast of emerging technologies, such as reconfigurable digital power chips, which can streamline power management in complex systems. This not only helps in waste reduction but also plays a crucial role in meeting the energy demands of advanced computing solutions, further establishing a more efficient and sustainable power supply ecosystem.

Essential Digital Strategies for Optimizing Power Supply Configurations

Optimizing power supply configurations is crucial for enhancing the overall efficiency of your programmable power supply system. By implementing essential digital strategies, you can streamline operations and maximize performance. One key tip is to regularly update the firmware of your power supply unit. Manufacturers often release updates that improve functionality and resolve bugs, ensuring your system runs smoothly and effectively.

Another important strategy is to utilize remote monitoring and control features. By leveraging digital interfaces, you can manage multiple power supplies from a single location. This not only saves time but also allows you to make real-time adjustments based on performance analytics. Additionally, employing automation scripts can help set your power supply parameters according to specific requirements, reducing the potential for human error and improving consistency in your operations.

Lastly, consider integrating data logging and analysis tools. Monitoring key performance indicators such as voltage stability, current fluctuations, and temperature variations can provide insights into your power supply's efficiency. Analyzing this data allows for proactive adjustments, ensuring your setups are always operating at peak performance. By embracing these digital strategies, you can significantly enhance the efficacy of your programmable power supply usage.

Monitoring and Analyzing Performance Data for Enhanced Efficiency

Efficient utilization of programmable power supplies (PPS) is pivotal in driving down operational costs and enhancing productivity in various industries. A critical aspect of maximizing efficiency lies in the monitoring and analyzing of performance data. According to a report by Technavio, the global programmable power supply market is projected to grow at a CAGR of 5.6% from 2021 to 2025, highlighting the increasing importance of effective power management strategies. By closely tracking the performance metrics such as voltage regulation, current loading, and thermal behavior, organizations can identify inefficiencies and optimize their power supply usage.

Efficient utilization of programmable power supplies (PPS) is pivotal in driving down operational costs and enhancing productivity in various industries. A critical aspect of maximizing efficiency lies in the monitoring and analyzing of performance data. According to a report by Technavio, the global programmable power supply market is projected to grow at a CAGR of 5.6% from 2021 to 2025, highlighting the increasing importance of effective power management strategies. By closely tracking the performance metrics such as voltage regulation, current loading, and thermal behavior, organizations can identify inefficiencies and optimize their power supply usage.

Data analytics tools play a significant role in this process. By integrating real-time monitoring systems, businesses can capture vital performance data that allows for detailed analysis. Gartner's research indicates that organizations leveraging these technologies are 30% more likely to improve their operational efficiency. For example, advanced analytics can reveal trends and anomalies in power consumption, enabling companies to make informed decisions about load distribution and system scaling. This systematic approach not only enhances efficiency but also significantly reduces downtime and maintenance costs, showcasing the critical link between data analysis and operational success in power supply management.

Integrating Automation Tools for Streamlined Power Supply Management

In the modern landscape of power supply management, integrating automation tools can significantly enhance efficiency and streamline operations. Programmable power supplies are invaluable in a variety of applications, from testing and development to production environments. By incorporating automation tools, users can eliminate manual errors, reduce setup times, and achieve precise control over power delivery. Automation not only ensures consistency in operations but also enables real-time monitoring and adjustments, providing a seamless integration into any workflow.

Utilizing software to automate the programming of power supplies allows engineers and technicians to focus on more critical tasks. For instance, by employing scripts or specialized software solutions, repetitive configurations can be performed automatically—freeing up time for innovation and development. Additionally, this automation can facilitate complex testing sequences, with conditions set to control power levels, voltages, and currents dynamically based on specific test parameters. Ultimately, embracing these digital strategies leads to a more efficient and productive environment, making power supply management not just easier but smarter.

Maximize Efficiency with These Digital Strategies for Your Programmable Power Supply Usage

| Strategy | Description | Benefits | Implementation Time (Weeks) |

|---|---|---|---|

| Automated Testing | Integrate automated testing systems to verify power supply performance. | Increased reliability and faster testing processes. | 4 |

| Remote Monitoring | Implement remote monitoring tools for power supply performance tracking. | Real-time insights and proactive issue detection. | 6 |

| Data Analytics | Utilize data analytics to assess historical performance data. | Informed decision-making and power optimization. | 8 |

| Predictive Maintenance | Implement predictive maintenance strategies based on usage data. | Reduced downtime and maintenance costs. | 5 |

| User Training | Train your team on the efficient use of power supply resources. | Enhanced operational efficiency and reduced errors. | 3 |

Best Practices for Troubleshooting Common Issues in Programmable Power Supplies

When working with programmable power supplies, troubleshooting common issues can save both time and resources. One of the first steps is to ensure proper connection and configurations. Double-check all wiring and settings to confirm they match the required specifications for your application. This foundational practice can prevent many problems from arising.

Tip 1: Use the built-in diagnostic features of your power supply. Many modern programmable units come with self-test functions that can quickly identify common faults. Familiarize yourself with these features to streamline your troubleshooting process.

Another common issue is voltage instability. This can often be resolved by checking for environmental factors such as temperature fluctuations and interference from nearby electronic devices. Ensuring stable operating conditions is crucial for maintaining consistent output.

Tip 2: Implement a regular maintenance routine. Regularly inspecting components, updating firmware, and recalibrating your power supply can help catch potential problems before they escalate into major issues.

By following these best practices, you can improve efficiency and dependability in your programmable power supply usage.

Related Posts

-

Innovative Applications of DC to DC Converters in Modern Electronics

-

10 Best DC to DC Converters You Should Consider For Your Next Project

-

10 Digital Best Practices for Enhancing Your Buck Converter Efficiency

-

Understanding the Differences in Power Supply Unit Technologies

-

10 Digital Tips for Optimizing Efficiency in DC DC Power Supply Systems

-

Innovative Solutions for AC to DC Inverter Applications

At Premium PSU, we are specialists in designing and manufacturing power conversion systems for the industrial market. Our product range includes high reliability power supplies from 50W to 72kW.

PREMIUM PSU

C/ Dolors Aleu, 19-21, 2nd Floor

08908 – Hospitalet de Llobregat

Barcelona-SPAIN

t.+34 93 223 26 85