Unlocking Efficiency: How Buck Converters Achieve Over 95% Power Conversion in Modern Electronics

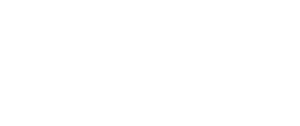

In the ever-evolving landscape of modern electronics, the quest for energy efficiency has never been more critical. Among the technologies leading this charge is the buck converter, a vital component in the power management sector. According to a recent report by Trends in Power Electronics, buck converters can achieve power conversion efficiencies surpassing 95%, making them essential for applications ranging from smartphones to electric vehicles. This remarkable efficiency not only reduces energy consumption but also minimizes the heat generated during operation, extending the lifespan of electronic devices. Furthermore, as global electricity demand continues to rise, the integration of efficient power conversion technologies like buck converters becomes increasingly important for meeting sustainability goals. This implies that designers and engineers must embrace these advancements to enhance performance while contributing to a greener future in electronics.

In the ever-evolving landscape of modern electronics, the quest for energy efficiency has never been more critical. Among the technologies leading this charge is the buck converter, a vital component in the power management sector. According to a recent report by Trends in Power Electronics, buck converters can achieve power conversion efficiencies surpassing 95%, making them essential for applications ranging from smartphones to electric vehicles. This remarkable efficiency not only reduces energy consumption but also minimizes the heat generated during operation, extending the lifespan of electronic devices. Furthermore, as global electricity demand continues to rise, the integration of efficient power conversion technologies like buck converters becomes increasingly important for meeting sustainability goals. This implies that designers and engineers must embrace these advancements to enhance performance while contributing to a greener future in electronics.

Efficiency Metrics: Understanding Why Buck Converters Exceed 95% Power Conversion Rates

Buck converters, widely used in modern electronics, stand out for their remarkable power conversion efficiency, often exceeding 95%. This impressive performance stems from their innovative design, which employs a switching mechanism to efficiently step down voltage. Unlike linear regulators, which dissipate excess voltage as heat, buck converters intelligently transfer energy, minimizing losses and enhancing overall efficiency. The ability to maintain high efficiency across varying loads and input voltages makes them particularly suitable for battery-operated devices, where energy conservation is paramount.

Understanding efficiency metrics is crucial for evaluating buck converters. Efficiency is typically calculated by dividing the output power by the input power, providing a clear indication of how effectively energy is utilized. In practical applications, factors such as switching frequency, load conditions, and thermal management play a significant role in achieving high conversion rates. As technology advances, newer materials and designs further push the boundaries of efficiency, allowing buck converters to not only excel in performance but also contribute to the sustainability goals of modern electronics. This constant evolution reaffirms the importance of buck converters in driving the future of energy-efficient technology.

Unlocking Efficiency: How Buck Converters Achieve Over 95% Power Conversion in Modern Electronics

| Parameter | Value | Units |

|---|---|---|

| Typical Efficiency | 95 | % |

| Maximum Output Current | 10 | A |

| Input Voltage Range | 4.5 - 25 | V |

| Output Voltage | 3.3 | V |

| Switching Frequency | 500 | kHz |

| Thermal Resistance | 45 | °C/W |

| Standby Current | 10 | mA |

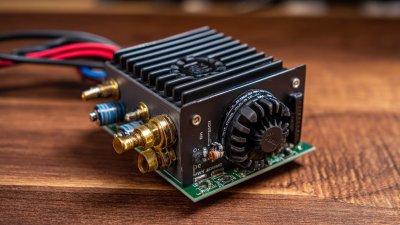

Thermal Management Techniques: Enhancing Performance and Longevity in Buck Converters

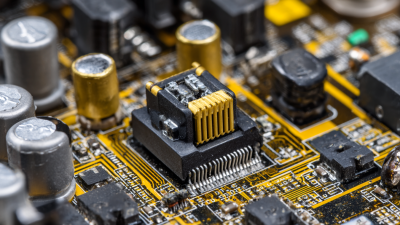

Effective thermal management is crucial for enhancing the performance and longevity of buck converters. As these devices operate with high efficiency, often exceeding 95%, they generate significant heat during the power conversion process. If not properly managed, this heat can lead to increased thermal stress, reduced efficiency, and ultimately device failure. To combat these challenges, various techniques such as heat sinks, thermal pads, and innovative PCB designs are employed to dissipate heat efficiently and maintain optimal operating temperatures.

One effective thermal management technique involves the use of advanced materials that improve heat dissipation capabilities. For example, using thermal interface materials (TIMs) can significantly enhance the thermal conductivity between the converter and heat sinks, minimizing hot spots. Moreover, implementing smart airflow designs can direct cool air over critical components, lowering overall operational temperatures.

Additionally, integrating temperature sensing and control systems allows for real-time monitoring, enabling proactive measures to be taken before overheating occurs, thereby extending the lifespan of buck converters in demanding applications.

Comparative Analysis: Buck Converters vs. Linear Regulators in Power Efficiency

In the realm of modern electronics, efficiency is paramount, particularly when it comes to power supply design. Buck converters have emerged as a superior choice over traditional linear regulators, primarily due to their exceptional power conversion capabilities. According to a report from Power Electronics Research, buck converters can achieve efficiencies exceeding 95%, making them ideal for applications where thermal management and energy savings are critical. In contrast, linear regulators typically exhibit efficiencies between 30% and 70%, as they dissipate excess voltage as heat rather than utilizing it for power conversion.

This efficiency gap is particularly significant in battery-powered devices, where extending battery life is crucial. A study by the International Journal of Electronics indicates that adopting buck converters in portable electronics can lead to a reduction in battery drain by nearly 20%, thereby enhancing performance and longevity. The ability to maintain high efficiency under varying load conditions also sets buck converters apart, offering an advantage in dynamic applications like smartphones and IoT devices. As industries continue to prioritize energy efficiency and sustainability, the advantages of buck converters become increasingly clear compared to linear regulators, paving the way for smarter and more efficient electronic systems.

Real-World Applications: Where High-Efficiency Buck Converters Are Making an Impact

In today’s fast-paced technological landscape, high-efficiency buck converters are playing a crucial role in various applications across multiple industries. Recent advancements have shown that these converters can achieve over 95% power conversion efficiency, significantly reducing energy losses in electronic devices. For instance, the development of a novel Buck-Boost Modified Series Forward (BBMSF) converter demonstrates how innovative designs can enhance performance, particularly in hybrid renewable energy systems, where efficiency is paramount.

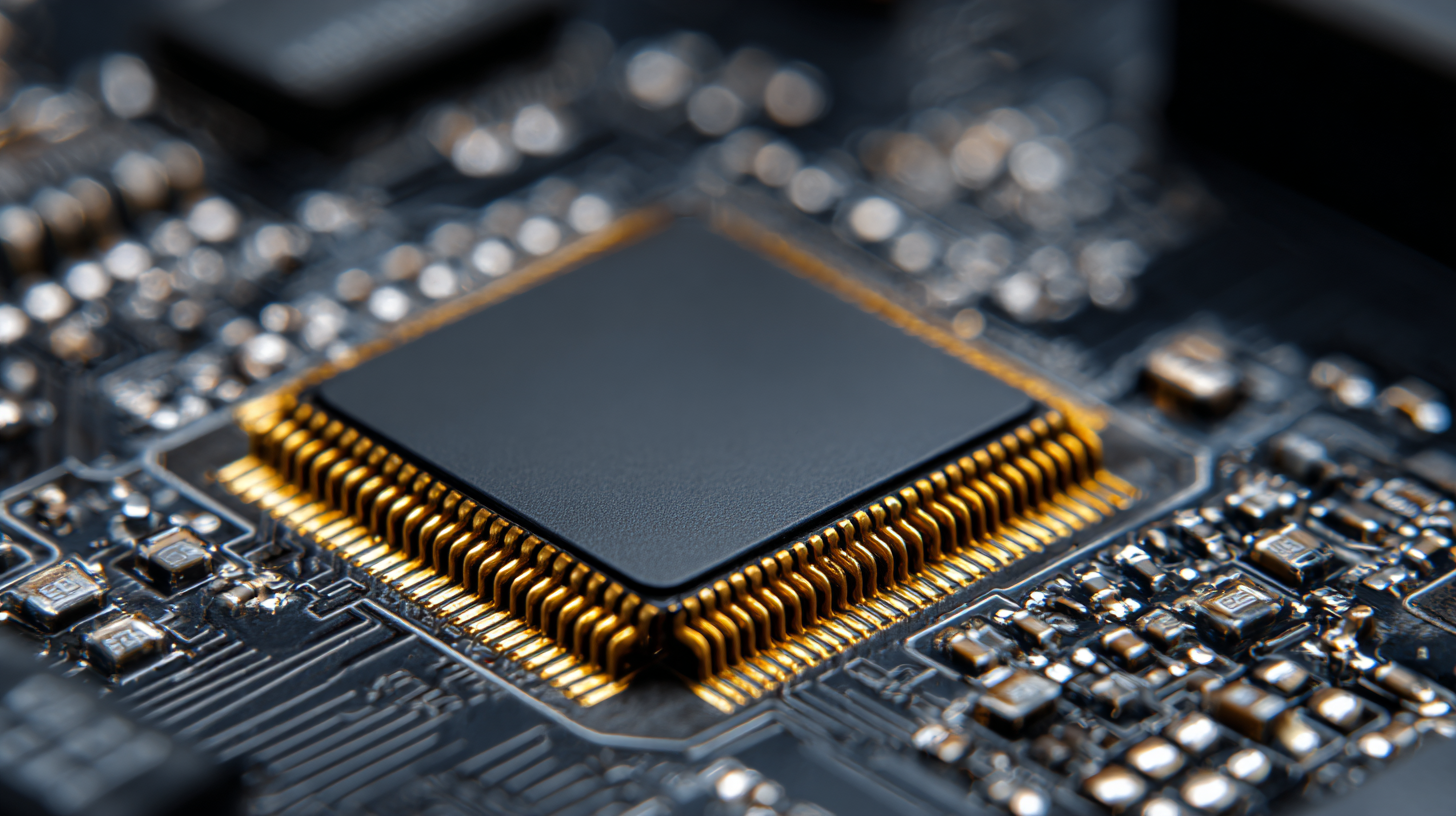

One notable application of high-efficiency buck converters is in electric vehicles (EVs). Reports have revealed that optimized DC-DC converters contribute to improved battery management systems by effectively managing power from multiple sources. As many vehicles transition to 48V systems, these converters are essential for ensuring efficiency and reliability under varying load conditions. Tip: When designing your system, consider converters that offer interleaving capabilities as they can significantly reduce ripple current and improve thermal performance.

Moreover, the rise of energy storage solutions further emphasizes the importance of efficient power conversion in managing renewable energy. Techniques like the use of high-efficiency poly-input DC–DC converters are paving the way for enhanced energy storage in EV applications, establishing a more sustainable future. Tip: It’s advisable to integrate advanced voltage multiplier rectifier circuits to improve performance in boost converter applications for your energy systems.

Efficiency of Buck Converters in Modern Electronics

This chart illustrates the efficiency of buck converters in various applications, showcasing their remarkable ability to maintain over 95% power conversion rates in real-world settings.

Future Trends: Innovations Driving Buck Converter Efficiency Beyond Current Standards

The automotive sector is witnessing a significant transformation driven by advancements in buck converter technology. As the demand for energy-efficient solutions grows, innovations in power conversion are enabling buck converters to achieve unprecedented efficiency levels exceeding 95%. This progress is crucial not only for enhancing the performance of electric vehicles (EVs) but also for extending the range and lifespan of their battery systems. Manufacturers are investing heavily in developing materials and designs that minimize energy losses, thereby responding to the pressures of sustainability and regulatory mandates for greener vehicles.

Looking ahead, the trajectory of the automotive DC-DC converter market remains robust, with expectations to rise from $3.68 billion in 2024 to an astonishing $29.95 billion by 2032, reflecting a remarkable CAGR of 29.9%. This growth will be fueled by continuous innovation in power electronics, including advanced control algorithms and integration of wide-bandgap semiconductors. As the automotive industry embraces electrification, the demand for cutting-edge buck converters will only increase, setting the stage for future breakthroughs that could redefine efficiency benchmarks and drive new standards in energy conversion.

Related Posts

-

10 Digital Best Practices for Enhancing Your Buck Converter Efficiency

-

How to Select the Best Buck Converter for Efficient Power Management in Your Application

-

Exploring the Future of Buck Converters at China's 138th Canton Fair 2025: Industry Insights and Innovations

-

Maximize Efficiency with These Digital Strategies for Your Programmable Power Supply Usage

-

Digital Solutions Tips for Optimizing Your DC DC Converter Performance

-

How to Choose the Right DC to AC Converter for Your Power Needs

At Premium PSU, we are specialists in designing and manufacturing power conversion systems for the industrial market. Our product range includes high reliability power supplies from 50W to 72kW.

PREMIUM PSU

C/ Dolors Aleu, 19-21, 2nd Floor

08908 – Hospitalet de Llobregat

Barcelona-SPAIN

t.+34 93 223 26 85